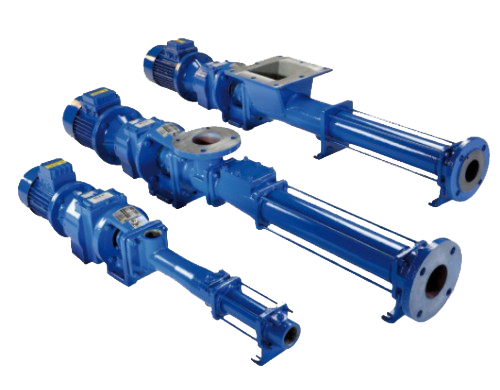

Progressive Cavity Screw Pump

Progressive Cavity/Screw pump that allows a certain volume of fluid to pass through a stator and rotor. It is not as accurate as a diaphragm/plunger pump and is only suitable for high viscosity fluids that have a self-lubricating effect to minimize wear.

Progressing cavity pumps or eccentric screw Pumps belong to the group of positive displacement pumps. The main components are the rotating rotor and stationary stator. The rotor, hinged or elastically attached on one side, is a round-threaded screw.

On the output side, the axial position oscillates. The hollow stator is elastic and has the same pitch length as the rotor. This leaves conveying spaces between the stator and the rotor, which move continuously from the inlet to the outlet side.

Good reason for buy:

- Design Standard: As per API 676

- Highest hygienic standard

- Optimum cleaning and low energy consumption

- Efficient and robust

- Low pulsation

- Gapless design

Technical Data

Capacity: Up to 1,50,000 LPH

Discharge Pressure: Up to 6 Bar g

Maximum Viscosity: Up to 1,00,000 cp

- Available in V Belt pulley & Gearmotor design

- Available in gland packing or mechanical seal design

Material of construction of wetted part:

Stator: Nitrile, Natural, EPDM, Viton, Silicon, Food grade

Rotor: SS 304, SS 316, SS 316L

Application & Industries

Water & waste water process

Food & Beverage Industries

Environmental & Energy industries

Pulp & Paper Industries

Sugar Industries

Winery, Brewery Industries